3D printing, also known as Additive Manufacturing, refers to a range of technologies used to translate a virtual computer-aided design (CAD) model data into physical resultant object. The basic principle common for all 3D printing technologies is layer-based-method where an object is made by adding successive layers of material to form the physical part. Each layer represents a thin cross-section of the object derived from the virtual CAD model. 3D printer software “slices” the final model into hundreds or thousands of horizontal 2D layers (“slices”). 3D printer reads every slice (2D image) and creates the object layer by layer. The thinner each layer is, the higher resolution of the final part will be. No matter which technology 3D printer uses, most 3D printing processes involve the following common steps:

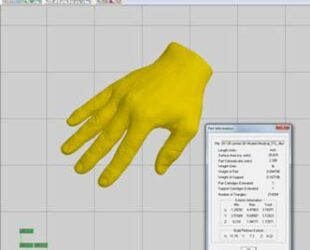

1. Computer-Aided Design (CAD) – The first step is to create a 3D model using computer-aided design (CAD) software. Laser and optical scanning can also be used to create 3D solid or surface representation of an object.

2. Conversion to STL – Nearly every 3D printer uses STL files which represent a standard file format for 3D printing in addition to some proprietary file types such as ZPR by Z Corporation and ObjDF by Objet Geometries. STL file defines the external closed surfaces of the original CAD model and forms the basis for calculation of the slices.

3. STL file transfer to 3D printer – The third step requires the transfer of the STL file to the 3D printer using its application software. The software usually has a visualization tool that allows the user to preview and manipulate the part(s) before printing. A proper positioning and sizing of the object on the build platform is important to maximize cost savings and reduce material waste.

4. Machine setup – It usually refers to selection of the printer resolution, material and other consumables refilling, build platform setup etc.

5. Build – It is an actual printing which is automated and computer controlled process. Depending on the object’s size, the printer and the resolution used, this process could take hours or even days to complete.

6. Parts removal – Remove the printed object from the printer. Precautions should be taken to avoid the parts damage during the removal process.

7. Post-processing – Many 3D printers will require some kind of post-processing for the printed object. It usually includes removal of support material and the model cleanup.

The 3D printing resolution and accuracy depend on the printer technology and material used. For a particular 3D printer the resolution depends on axis with highest resolution achieved on the vertical axis usually corresponding to layer thickness. Typical layer thickness is 0.1 mm, although some printer using material jetting technology may have layer thicknesses of 0.01 mm. In general, higher resolution requires longer printing time and many 3D printers have the capacity to vary the resolution. Lower resolution models are faster to build but are less precise.

American Society for Testing and Materials (ASTM) group classified the Additive Manufacturing (3D printing) technologies into 7 categories presented here with typical materials used: