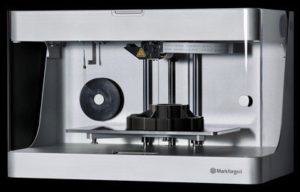

The Mark Two delivers industrial grade build quality and part strength in a desktop form-factor. It is the only printer available on market capable of printing composite plastic with the strength of aluminum and great level of details. The printer offers the flexibility to choose between different material options such as Chopped Carbon fiber filled Nylon with continuous Carbon Fiber or Kevlar or high temp/strength Fiberglass. From prototypes to production the printer is suitable for a variety of applications including surgical instruments prototyping, medical models printing and 3D printing of plastic composites that are transparent to X-rays.

For additional information about the printer, use and printing costs please contact Dario Bogojevic.

Technical Specifications:

Build Volume: 320 mm x 132 mm x 154 mm

Plastic Materials: Onyx

Fiber Materials: Carbon Fiber, Fiberglass, Kevlar, HSHT Fiberglass (High-Strength High- Temperature Fiberglass)

Z Layer Resolution: 100 micron

The Mark Two is FDM type printer that prints with two printheads: one builds Onyx parts, and the other is a revolutionary, new composite print head to reinforce those parts with continuous fiber. This printer also comes with MarkForged’s cloud-based 3D printing software, Eiger, which is user friendly, and runs on any computer system. The Mark Two print bed also clicks into place with 10 micron accuracy, and if you are adding components, it allows you to remove the print bed, integrate components, and then return the bed and put the printer right back into process.

Onyx is chopped carbon fiber filled Nylon. It is 1.4 times stronger and stiffer than ABS plastic, Onyx can be reinforced with any continuous fiber. Onyx sets the bar for surface finish, chemical resistivity, and heat tolerance.

Mark Two User Guides: